Categories

ASA Synthetic Resin Roof Tile

ASA PVC Anti-UV Roof Tile

APVC Anti Corrosion Roof Tile

Polycarbonate Roof Tile

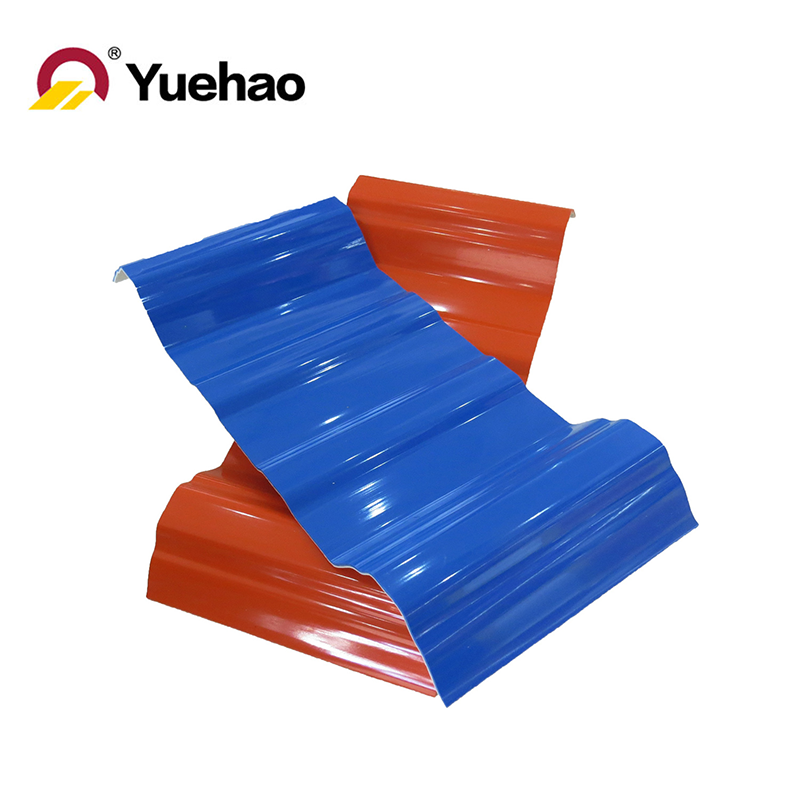

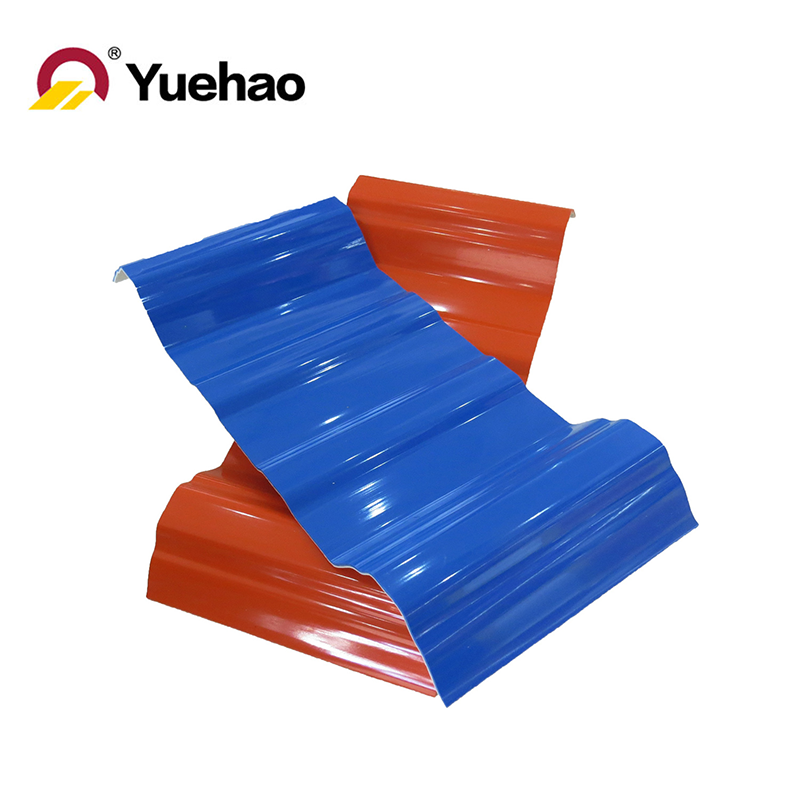

Efficient Installation APVC Roof Tile Roofing Sheet

Business type:Manufacturer

Brand:YUEHAO

Origin:Foshan, GD, China

Target market:South America, Mid-East, Africa, Asia

Grade:A,B

MOQ:200 SQM

Supply ability:10000SQM/DAY

Delivery time:3 to 15 days

Certificate:ISO, SGS ,FQM,MA,AL

Loading port:Sanshui/Guangzhou/Shenzhen, Guangdong, CN

Payment terms:L/C, D/A, D/P, T/T, Western Union, Money Gram

Packing:Nude Packing or pallet packing, customized.

-

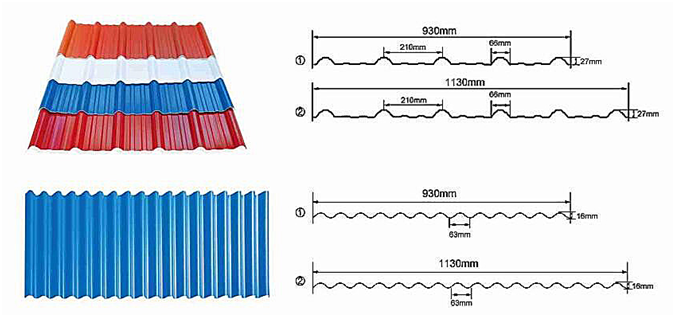

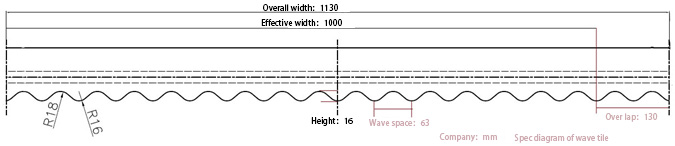

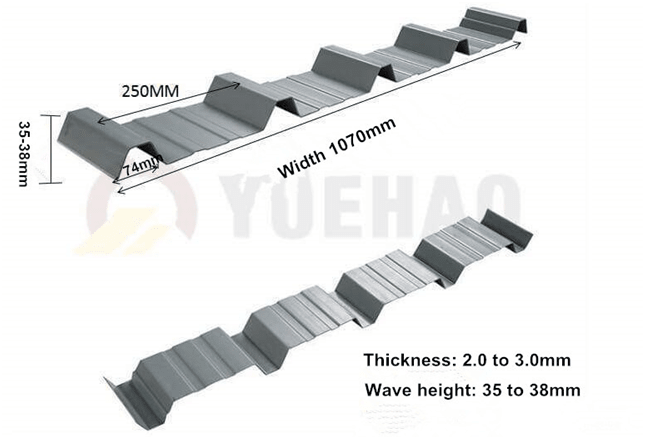

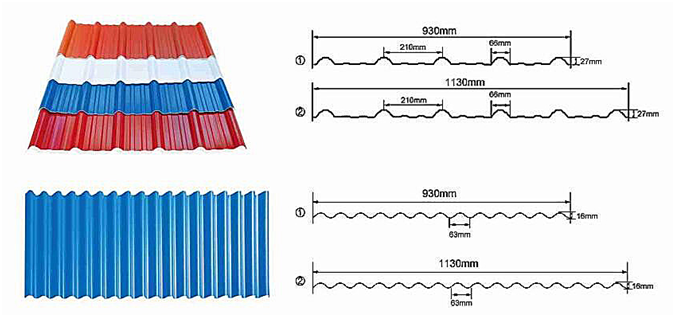

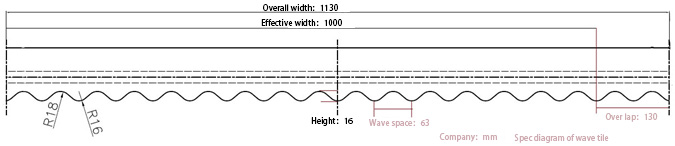

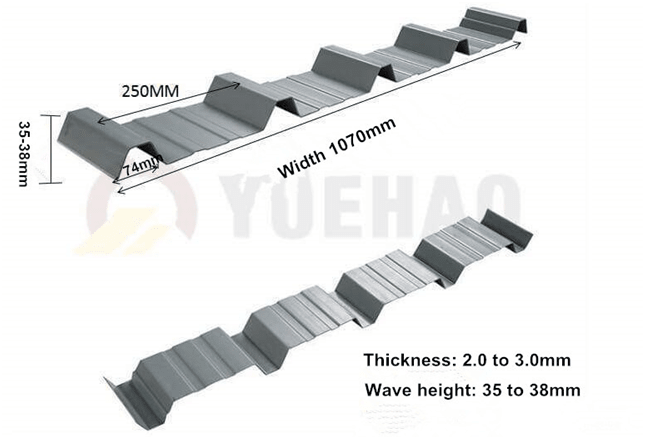

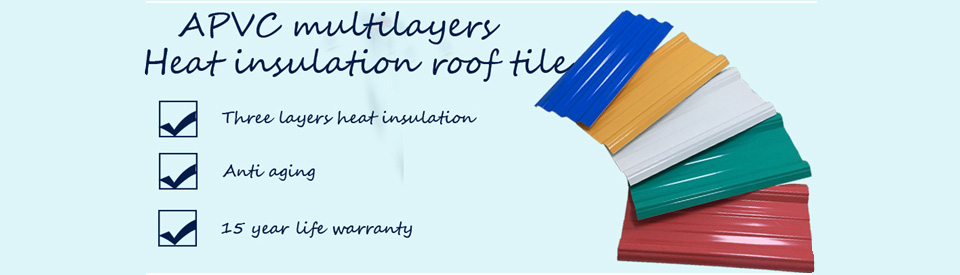

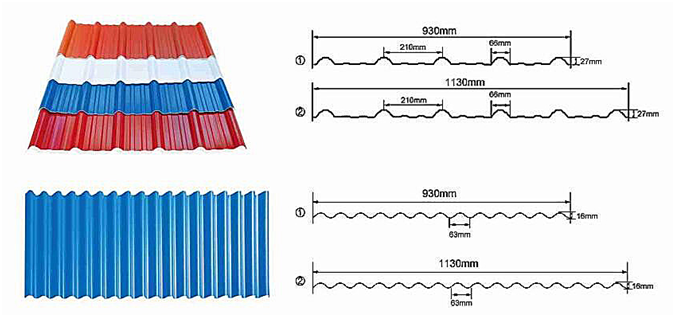

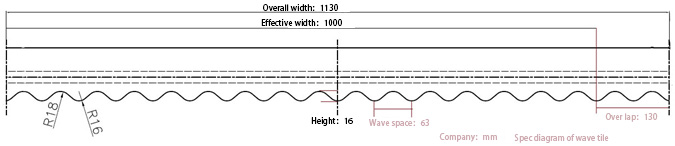

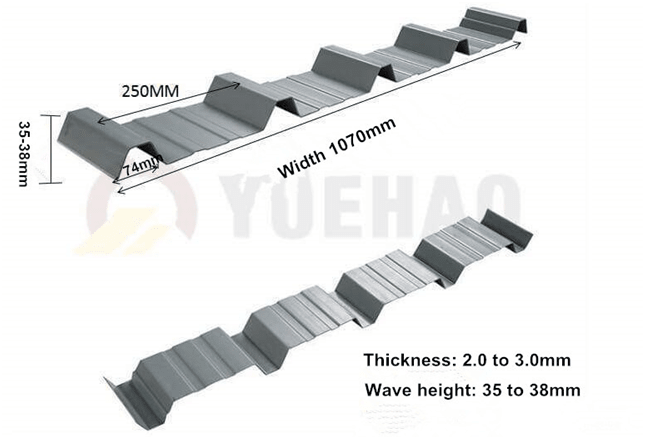

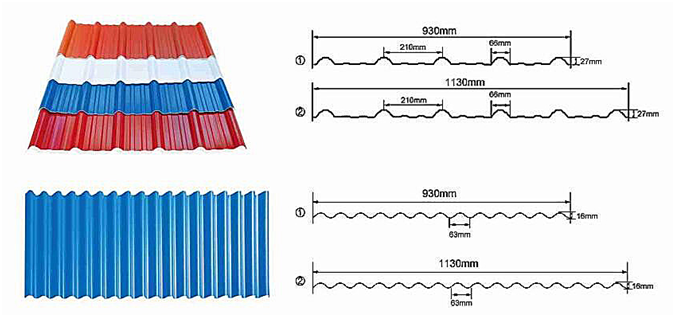

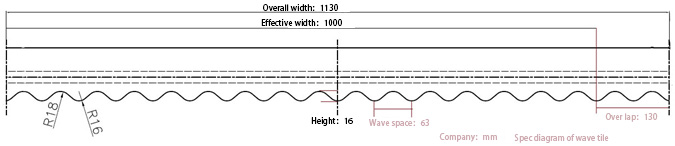

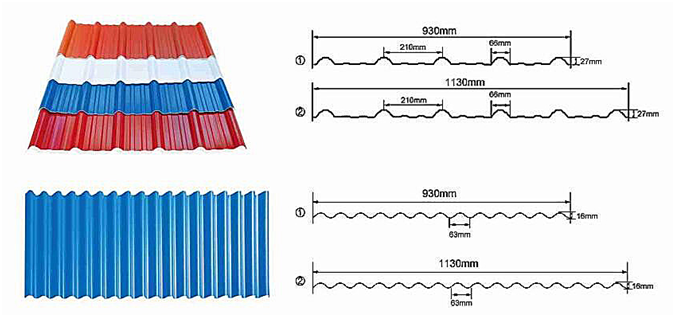

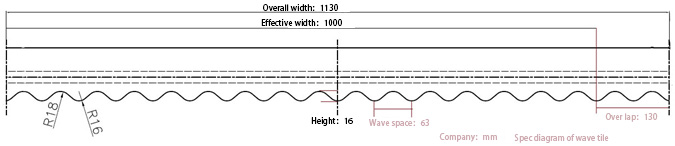

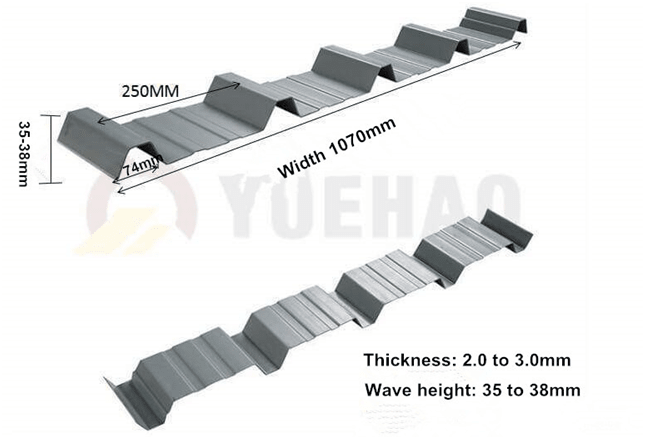

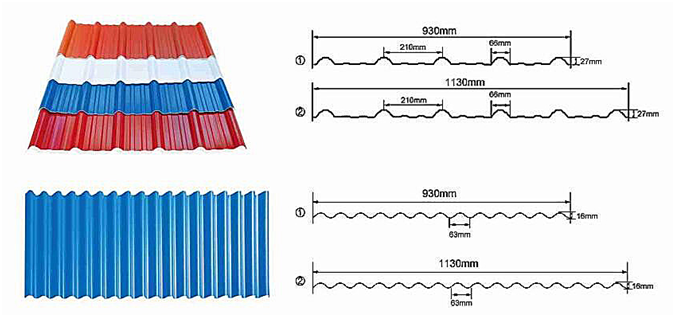

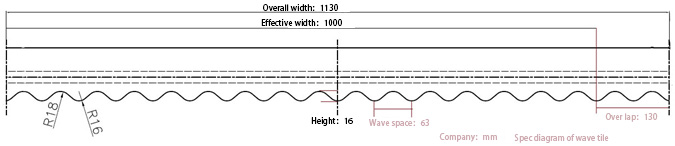

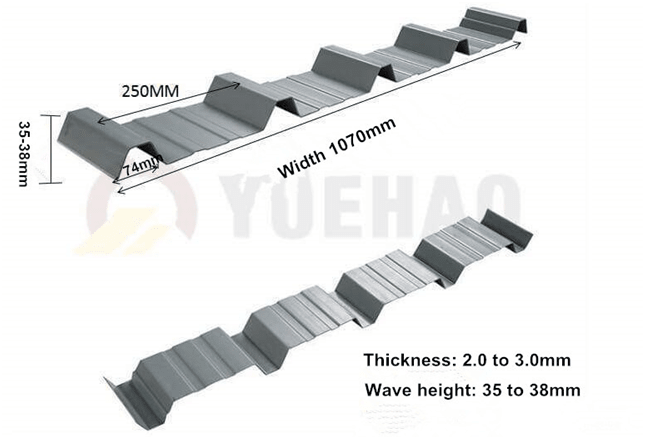

Overall Width: 930mm/1130mm

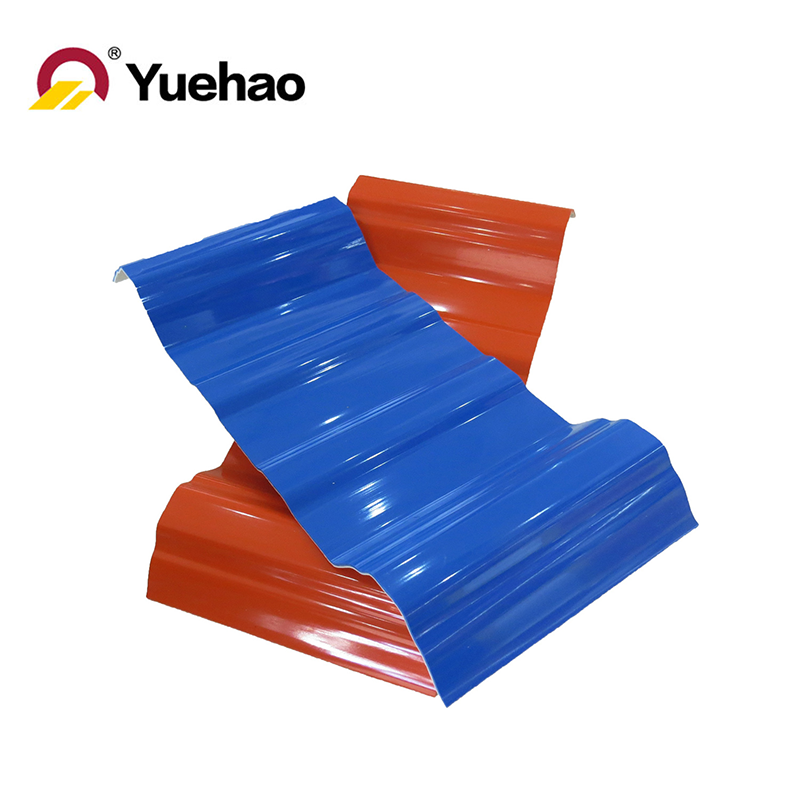

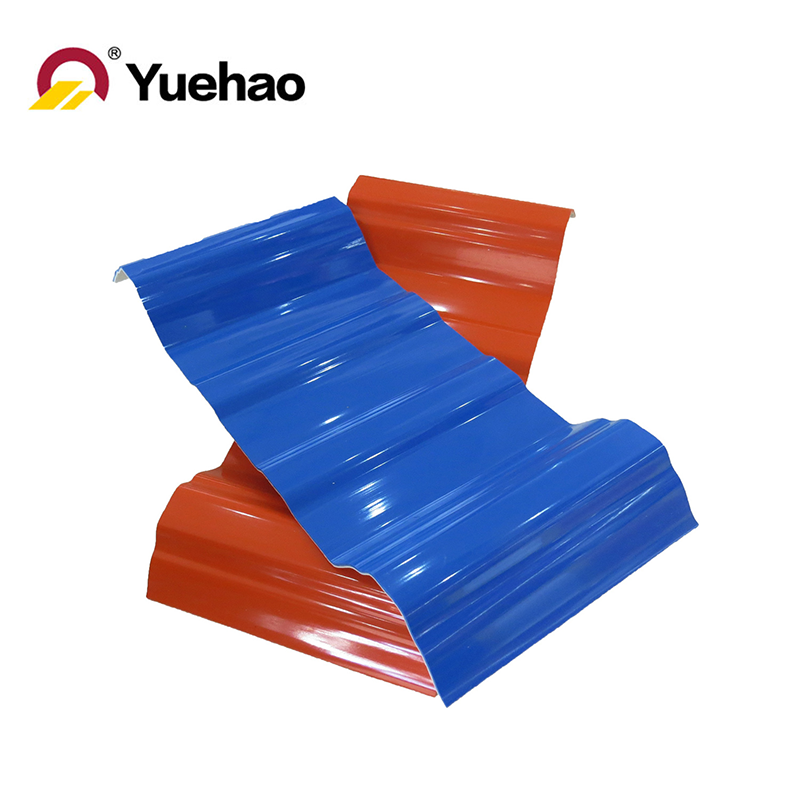

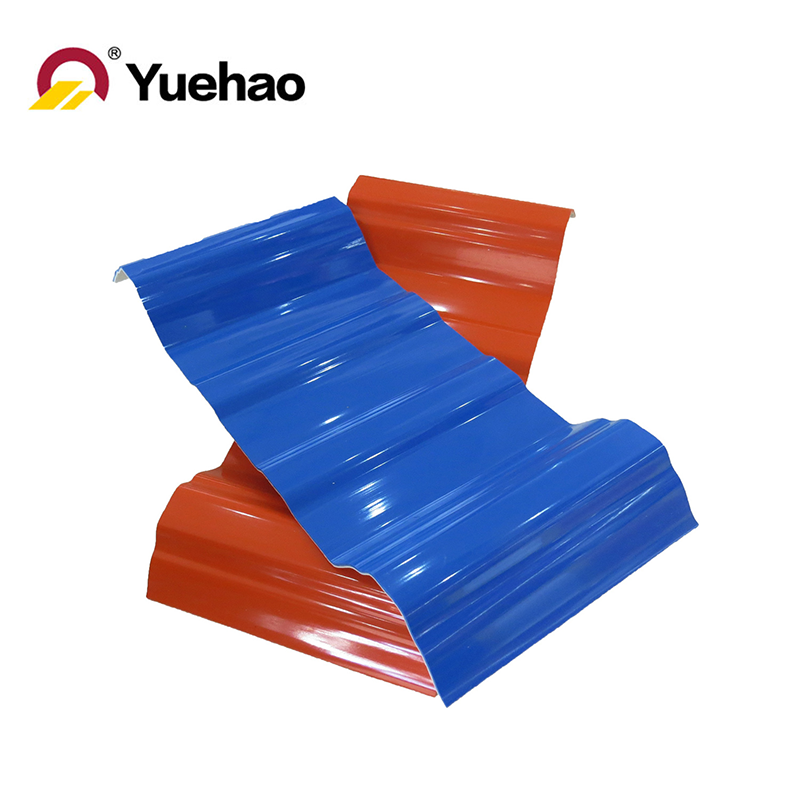

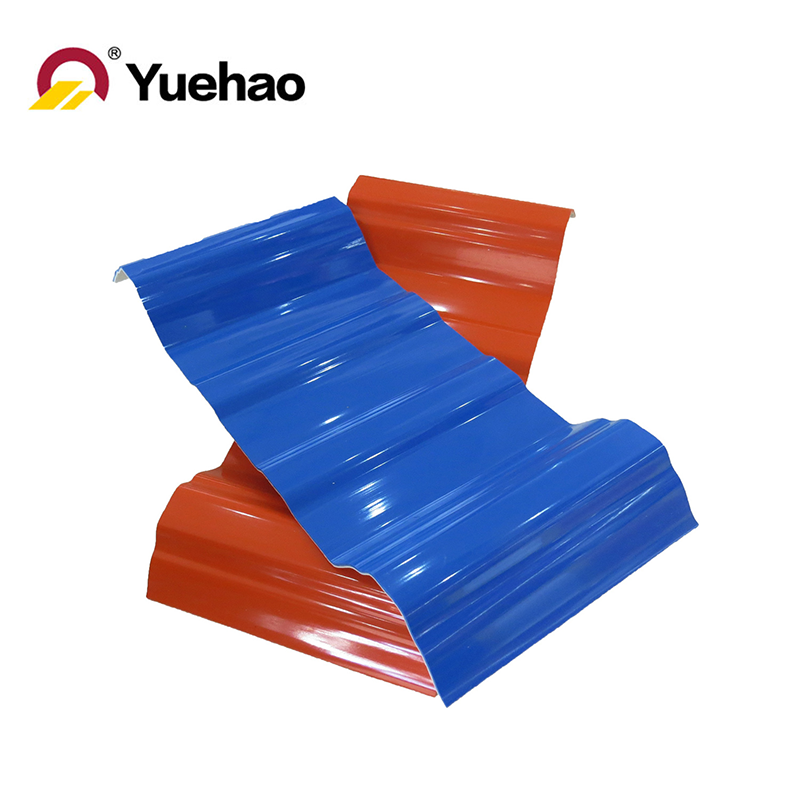

Color: White , Bule , Green , Yellow , Red , Dark Green , or Customized

Length: Customized

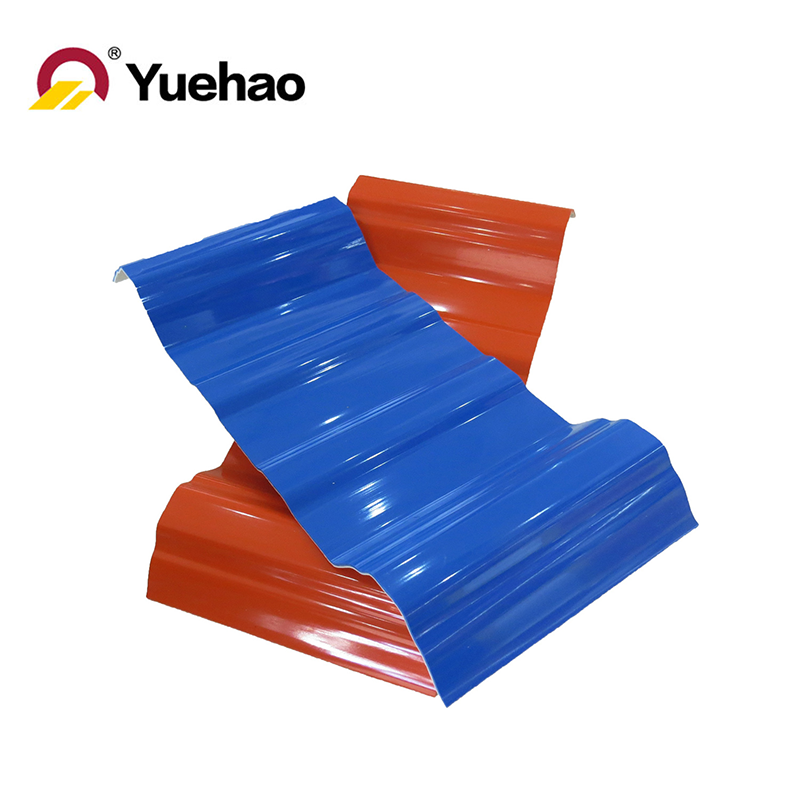

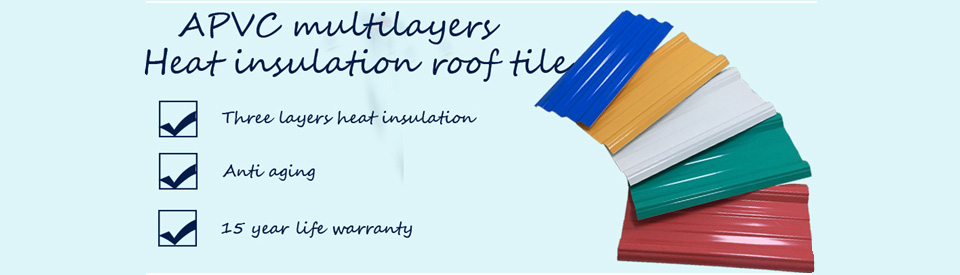

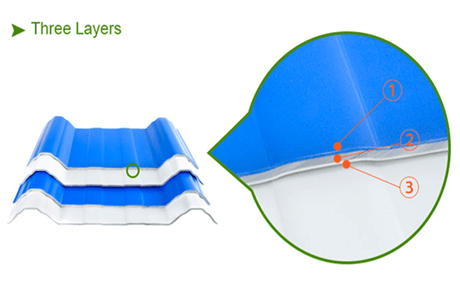

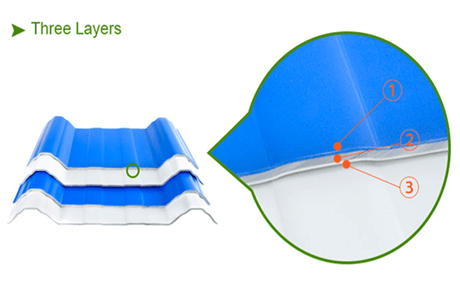

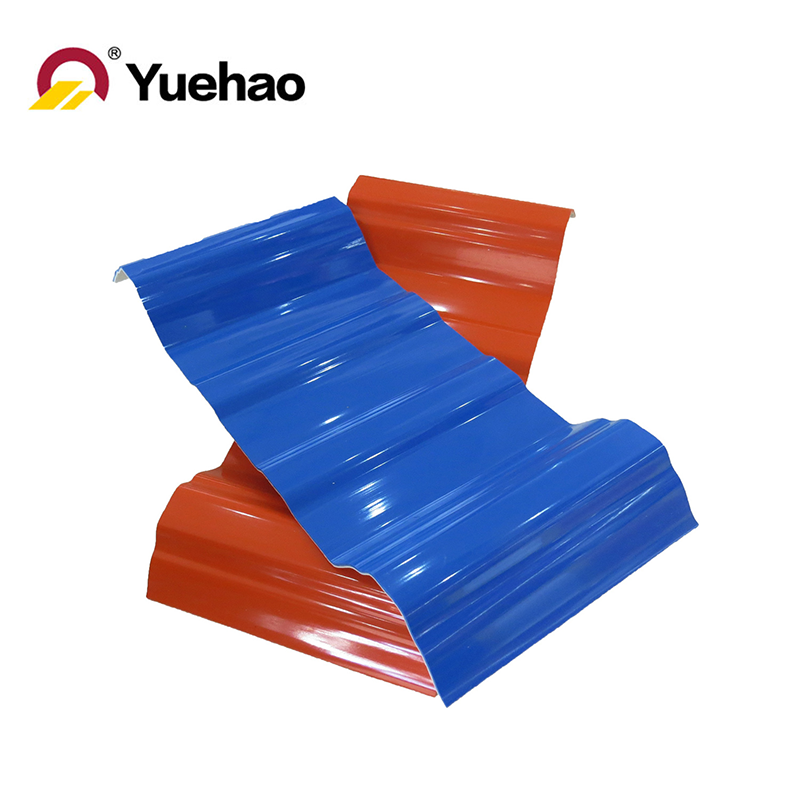

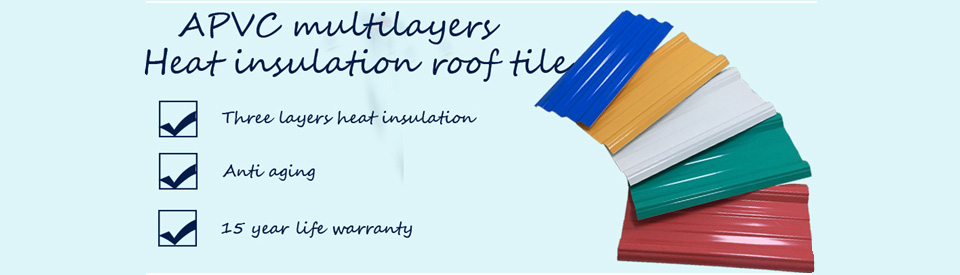

STRUCTURE AND MATERIALS

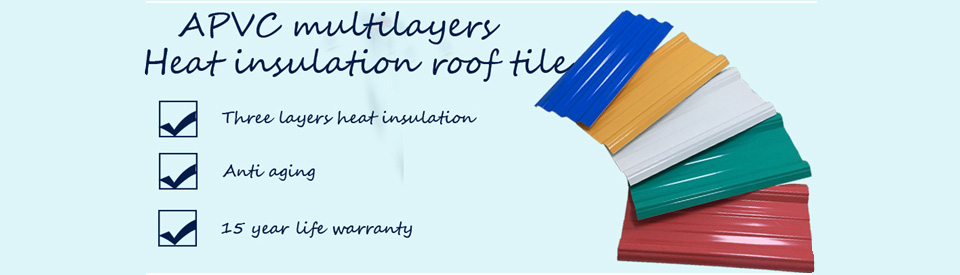

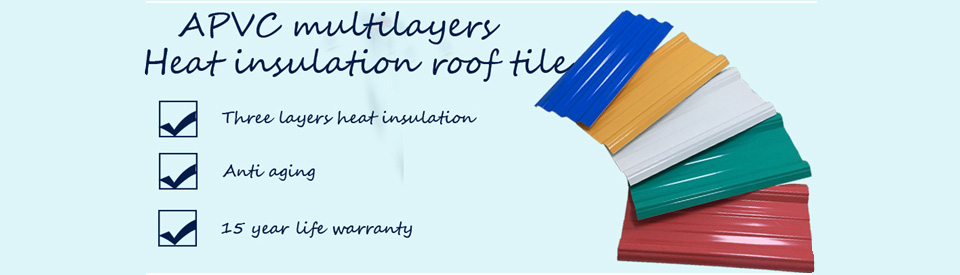

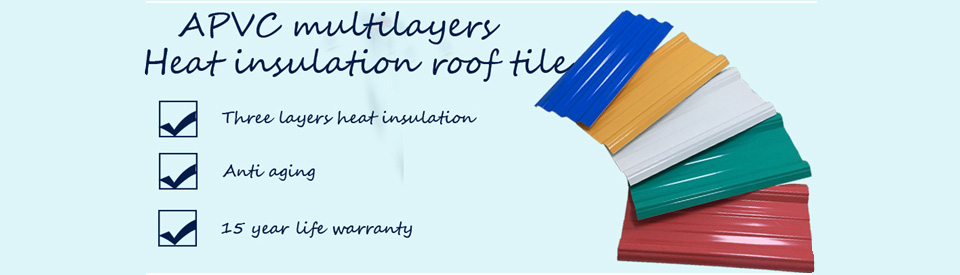

Yuehao APVC developed based on multi-layer co-extrusion technology through one-off processing, especially for corrosive substance manufacturing factories and areas with frequent acid rain. 2.3 or 4 layer co-extruded APVC sheeting materials are all available with each layer offering distictive feature.

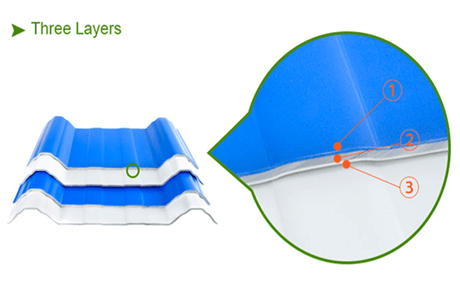

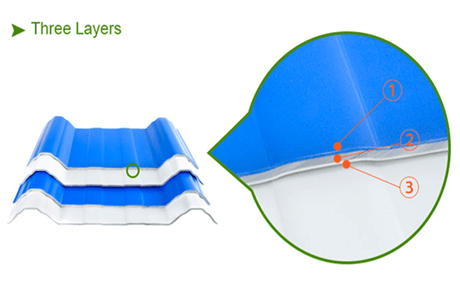

✔The first layer(surface):

The surface is made of engineering resin developed by the famous company SABIC. This special material renders the sheets with great feature of corrosion resisting and light reflecting. What’s more, APVC sheet are very distinguishable at resisting weather change.

✔The second layer:

The middle layer adopts modified PVC which ensures toughness and stiffness. Meanwhile, with heat insulated material involved, APVC sheet work excellently at heat proofing and reflecting.

✔The bottom layer:

The white bottom layer is materials with outstanding abrasion durability, enabling buildings to be more spacious and brighter.

PRODUCT ADVANTAGES

TECHNICAL DATA

No.

Content

Unit

Standard

Result

1

Appearance quality

-----

Homogeneous color, no bubble, no crack and no visible material in surface. Clean and no rag in telos.

Eligible

Eligible

Regular wave shape for two sides’ lapping

Eligible

2

Length

mm

+10

+2

Eligible

3

Width

mm

+5

+1

Eligible

4

Thickness

mm

±0.2

0.06

Eligible

5

Wave height

mm

±1.2

+0.04

Eligible

6

Wave space

mm

±2.0

0

Eligible

7

Density

Kg/m3

1000~1450

1442

Eligible

8

Tensile strength

≥20

26

Eligible

9

Elongation at break

≥20

38

Eligible

10

Falling ball impact (1kg,1.5m)

Should be no hole and crack

/

Eligible

11

Acid resistance(Volume fraction:20% NaOH,24H)

Should be no distinctive color change and no deformation

/

Eligible

12

Alkali resistance (mass fraction 20% NaOH,24H)

Should be no distinctive color change and no deformation

/

Eligible

13

Bending

≤50

12

Eligible

14

Oxygen Index

%

≥32

35

SPECIFICATION

PROCESS

Categories

ASA PVC Anti-UV Roof Tile

APVC Anti Corrosion Roof Tile

Polycarbonate Roof Tile

Efficient Installation APVC Roof Tile Roofing Sheet

Business type:Manufacturer

Brand:YUEHAO

Origin:Foshan, GD, China

Target market:South America, Mid-East, Africa, Asia

Grade:A,B

MOQ:200 SQM

Supply ability:10000SQM/DAY

Delivery time:3 to 15 days

Certificate:ISO, SGS ,FQM,MA,AL

Loading port:Sanshui/Guangzhou/Shenzhen, Guangdong, CN

Payment terms:L/C, D/A, D/P, T/T, Western Union, Money Gram

Packing:Nude Packing or pallet packing, customized.

-

Overall Width: 930mm/1130mm

Color: White , Bule , Green , Yellow , Red , Dark Green , or Customized

Length: Customized

STRUCTURE AND MATERIALS

Yuehao APVC developed based on multi-layer co-extrusion technology through one-off processing, especially for corrosive substance manufacturing factories and areas with frequent acid rain. 2.3 or 4 layer co-extruded APVC sheeting materials are all available with each layer offering distictive feature.

✔The first layer(surface):

The surface is made of engineering resin developed by the famous company SABIC. This special material renders the sheets with great feature of corrosion resisting and light reflecting. What’s more, APVC sheet are very distinguishable at resisting weather change.

✔The second layer:

The middle layer adopts modified PVC which ensures toughness and stiffness. Meanwhile, with heat insulated material involved, APVC sheet work excellently at heat proofing and reflecting.

✔The bottom layer:

The white bottom layer is materials with outstanding abrasion durability, enabling buildings to be more spacious and brighter.

PRODUCT ADVANTAGES

TECHNICAL DATA

No.

Content

Unit

Standard

Result

1

Appearance quality

-----

Homogeneous color, no bubble, no crack and no visible material in surface. Clean and no rag in telos.

Eligible

Eligible

Regular wave shape for two sides’ lapping

Eligible

2

Length

mm

+10

+2

Eligible

3

Width

mm

+5

+1

Eligible

4

Thickness

mm

±0.2

0.06

Eligible

5

Wave height

mm

±1.2

+0.04

Eligible

6

Wave space

mm

±2.0

0

Eligible

7

Density

Kg/m3

1000~1450

1442

Eligible

8

Tensile strength

≥20

26

Eligible

9

Elongation at break

≥20

38

Eligible

10

Falling ball impact (1kg,1.5m)

Should be no hole and crack

/

Eligible

11

Acid resistance(Volume fraction:20% NaOH,24H)

Should be no distinctive color change and no deformation

/

Eligible

12

Alkali resistance (mass fraction 20% NaOH,24H)

Should be no distinctive color change and no deformation

/

Eligible

13

Bending

≤50

12

Eligible

14

Oxygen Index

%

≥32

35

SPECIFICATION

PROCESS

Categories

APVC Anti Corrosion Roof Tile

Polycarbonate Roof Tile

Efficient Installation APVC Roof Tile Roofing Sheet

Business type:Manufacturer

Brand:YUEHAO

Origin:Foshan, GD, China

Target market:South America, Mid-East, Africa, Asia

Grade:A,B

MOQ:200 SQM

Supply ability:10000SQM/DAY

Delivery time:3 to 15 days

Certificate:ISO, SGS ,FQM,MA,AL

Loading port:Sanshui/Guangzhou/Shenzhen, Guangdong, CN

Payment terms:L/C, D/A, D/P, T/T, Western Union, Money Gram

Packing:Nude Packing or pallet packing, customized.

-

Overall Width: 930mm/1130mm

Color: White , Bule , Green , Yellow , Red , Dark Green , or Customized

Length: Customized

STRUCTURE AND MATERIALS

Yuehao APVC developed based on multi-layer co-extrusion technology through one-off processing, especially for corrosive substance manufacturing factories and areas with frequent acid rain. 2.3 or 4 layer co-extruded APVC sheeting materials are all available with each layer offering distictive feature.

✔The first layer(surface):

The surface is made of engineering resin developed by the famous company SABIC. This special material renders the sheets with great feature of corrosion resisting and light reflecting. What’s more, APVC sheet are very distinguishable at resisting weather change.

✔The second layer:

The middle layer adopts modified PVC which ensures toughness and stiffness. Meanwhile, with heat insulated material involved, APVC sheet work excellently at heat proofing and reflecting.

✔The bottom layer:

The white bottom layer is materials with outstanding abrasion durability, enabling buildings to be more spacious and brighter.

PRODUCT ADVANTAGES

TECHNICAL DATA

No.

Content

Unit

Standard

Result

1

Appearance quality

-----

Homogeneous color, no bubble, no crack and no visible material in surface. Clean and no rag in telos.

Eligible

Eligible

Regular wave shape for two sides’ lapping

Eligible

2

Length

mm

+10

+2

Eligible

3

Width

mm

+5

+1

Eligible

4

Thickness

mm

±0.2

0.06

Eligible

5

Wave height

mm

±1.2

+0.04

Eligible

6

Wave space

mm

±2.0

0

Eligible

7

Density

Kg/m3

1000~1450

1442

Eligible

8

Tensile strength

≥20

26

Eligible

9

Elongation at break

≥20

38

Eligible

10

Falling ball impact (1kg,1.5m)

Should be no hole and crack

/

Eligible

11

Acid resistance(Volume fraction:20% NaOH,24H)

Should be no distinctive color change and no deformation

/

Eligible

12

Alkali resistance (mass fraction 20% NaOH,24H)

Should be no distinctive color change and no deformation

/

Eligible

13

Bending

≤50

12

Eligible

14

Oxygen Index

%

≥32

35

SPECIFICATION

PROCESS

Categories

Polycarbonate Roof Tile

Efficient Installation APVC Roof Tile Roofing Sheet

Business type:Manufacturer

Brand:YUEHAO

Origin:Foshan, GD, China

Target market:South America, Mid-East, Africa, Asia

Grade:A,B

MOQ:200 SQM

Supply ability:10000SQM/DAY

Delivery time:3 to 15 days

Certificate:ISO, SGS ,FQM,MA,AL

Loading port:Sanshui/Guangzhou/Shenzhen, Guangdong, CN

Payment terms:L/C, D/A, D/P, T/T, Western Union, Money Gram

Packing:Nude Packing or pallet packing, customized.

-

Overall Width: 930mm/1130mm

Color: White , Bule , Green , Yellow , Red , Dark Green , or Customized

Length: Customized

STRUCTURE AND MATERIALS

Yuehao APVC developed based on multi-layer co-extrusion technology through one-off processing, especially for corrosive substance manufacturing factories and areas with frequent acid rain. 2.3 or 4 layer co-extruded APVC sheeting materials are all available with each layer offering distictive feature.

✔The first layer(surface):

The surface is made of engineering resin developed by the famous company SABIC. This special material renders the sheets with great feature of corrosion resisting and light reflecting. What’s more, APVC sheet are very distinguishable at resisting weather change.

✔The second layer:

The middle layer adopts modified PVC which ensures toughness and stiffness. Meanwhile, with heat insulated material involved, APVC sheet work excellently at heat proofing and reflecting.

✔The bottom layer:

The white bottom layer is materials with outstanding abrasion durability, enabling buildings to be more spacious and brighter.

PRODUCT ADVANTAGES

TECHNICAL DATA

No.

Content

Unit

Standard

Result

1

Appearance quality

-----

Homogeneous color, no bubble, no crack and no visible material in surface. Clean and no rag in telos.

Eligible

Eligible

Regular wave shape for two sides’ lapping

Eligible

2

Length

mm

+10

+2

Eligible

3

Width

mm

+5

+1

Eligible

4

Thickness

mm

±0.2

0.06

Eligible

5

Wave height

mm

±1.2

+0.04

Eligible

6

Wave space

mm

±2.0

0

Eligible

7

Density

Kg/m3

1000~1450

1442

Eligible

8

Tensile strength

≥20

26

Eligible

9

Elongation at break

≥20

38

Eligible

10

Falling ball impact (1kg,1.5m)

Should be no hole and crack

/

Eligible

11

Acid resistance(Volume fraction:20% NaOH,24H)

Should be no distinctive color change and no deformation

/

Eligible

12

Alkali resistance (mass fraction 20% NaOH,24H)

Should be no distinctive color change and no deformation

/

Eligible

13

Bending

≤50

12

Eligible

14

Oxygen Index

%

≥32

35

SPECIFICATION

PROCESS

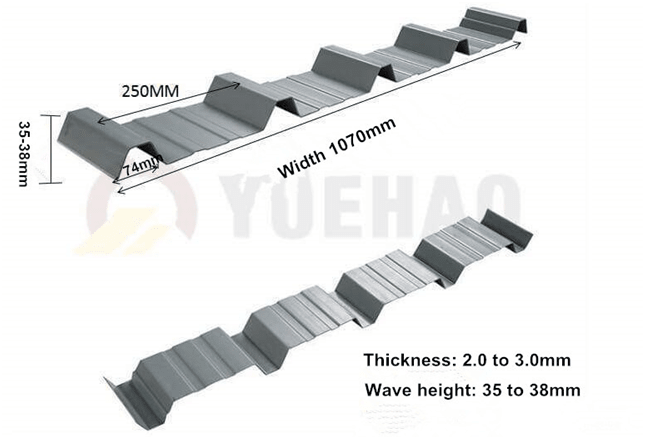

Efficient Installation APVC Roof Tile Roofing Sheet

Business type:Manufacturer

Brand:YUEHAO

Origin:Foshan, GD, China

Target market:South America, Mid-East, Africa, Asia

Grade:A,B

MOQ:200 SQM

Supply ability:10000SQM/DAY

Delivery time:3 to 15 days

Certificate:ISO, SGS ,FQM,MA,AL

Loading port:Sanshui/Guangzhou/Shenzhen, Guangdong, CN

Payment terms:L/C, D/A, D/P, T/T, Western Union, Money Gram

Packing:Nude Packing or pallet packing, customized.

-

Overall Width: 930mm/1130mm

Color: White , Bule , Green , Yellow , Red , Dark Green , or Customized

Length: Customized

STRUCTURE AND MATERIALS

Yuehao APVC developed based on multi-layer co-extrusion technology through one-off processing, especially for corrosive substance manufacturing factories and areas with frequent acid rain. 2.3 or 4 layer co-extruded APVC sheeting materials are all available with each layer offering distictive feature.

✔The first layer(surface):

The surface is made of engineering resin developed by the famous company SABIC. This special material renders the sheets with great feature of corrosion resisting and light reflecting. What’s more, APVC sheet are very distinguishable at resisting weather change.

✔The second layer:

The middle layer adopts modified PVC which ensures toughness and stiffness. Meanwhile, with heat insulated material involved, APVC sheet work excellently at heat proofing and reflecting.

✔The bottom layer:

The white bottom layer is materials with outstanding abrasion durability, enabling buildings to be more spacious and brighter.

PRODUCT ADVANTAGES

TECHNICAL DATA

No.

Content

Unit

Standard

Result

1

Appearance quality

-----

Homogeneous color, no bubble, no crack and no visible material in surface. Clean and no rag in telos.

Eligible

Eligible

Regular wave shape for two sides’ lapping

Eligible

2

Length

mm

+10

+2

Eligible

3

Width

mm

+5

+1

Eligible

4

Thickness

mm

±0.2

0.06

Eligible

5

Wave height

mm

±1.2

+0.04

Eligible

6

Wave space

mm

±2.0

0

Eligible

7

Density

Kg/m3

1000~1450

1442

Eligible

8

Tensile strength

≥20

26

Eligible

9

Elongation at break

≥20

38

Eligible

10

Falling ball impact (1kg,1.5m)

Should be no hole and crack

/

Eligible

11

Acid resistance(Volume fraction:20% NaOH,24H)

Should be no distinctive color change and no deformation

/

Eligible

12

Alkali resistance (mass fraction 20% NaOH,24H)

Should be no distinctive color change and no deformation

/

Eligible

13

Bending

≤50

12

Eligible

14

Oxygen Index

%

≥32

35

SPECIFICATION

PROCESS

Efficient Installation APVC Roof Tile Roofing Sheet

Brand:YUEHAO

Origin:Foshan, GD, China

Target market:South America, Mid-East, Africa, Asia

Grade:A,B

MOQ:200 SQM

Supply ability:10000SQM/DAY

Delivery time:3 to 15 days

Certificate:ISO, SGS ,FQM,MA,AL

Loading port:Sanshui/Guangzhou/Shenzhen, Guangdong, CN

Payment terms:L/C, D/A, D/P, T/T, Western Union, Money Gram

Packing:Nude Packing or pallet packing, customized.

Overall Width: 930mm/1130mm

Color: White , Bule , Green , Yellow , Red , Dark Green , or Customized

Length: Customized

STRUCTURE AND MATERIALS

Yuehao APVC developed based on multi-layer co-extrusion technology through one-off processing, especially for corrosive substance manufacturing factories and areas with frequent acid rain. 2.3 or 4 layer co-extruded APVC sheeting materials are all available with each layer offering distictive feature.

✔The first layer(surface):

The surface is made of engineering resin developed by the famous company SABIC. This special material renders the sheets with great feature of corrosion resisting and light reflecting. What’s more, APVC sheet are very distinguishable at resisting weather change.

✔The second layer:

The middle layer adopts modified PVC which ensures toughness and stiffness. Meanwhile, with heat insulated material involved, APVC sheet work excellently at heat proofing and reflecting.

✔The bottom layer:

The white bottom layer is materials with outstanding abrasion durability, enabling buildings to be more spacious and brighter.

PRODUCT ADVANTAGES

TECHNICAL DATA

| No. | Content | Unit | Standard | Result | |

| 1 |

Appearance quality |

----- |

Homogeneous color, no bubble, no crack and no visible material in surface. Clean and no rag in telos. | Eligible | Eligible |

| Regular wave shape for two sides’ lapping | Eligible | ||||

| 2 | Length | mm | +10 | +2 | Eligible |

| 3 | Width | mm | +5 | +1 | Eligible |

| 4 | Thickness | mm | ±0.2 | 0.06 | Eligible |

| 5 | Wave height | mm | ±1.2 | +0.04 | Eligible |

| 6 | Wave space | mm | ±2.0 | 0 | Eligible |

| 7 | Density | Kg/m3 | 1000~1450 | 1442 | Eligible |

| 8 | Tensile strength | ≥20 | 26 | Eligible | |

| 9 | Elongation at break | ≥20 | 38 | Eligible | |

| 10 | Falling ball impact (1kg,1.5m) | Should be no hole and crack | / | Eligible | |

| 11 | Acid resistance(Volume fraction:20% NaOH,24H) | Should be no distinctive color change and no deformation | / | Eligible | |

| 12 | Alkali resistance (mass fraction 20% NaOH,24H) | Should be no distinctive color change and no deformation | / | Eligible | |

| 13 | Bending | ≤50 | 12 | Eligible | |

| 14 | Oxygen Index | % | ≥32 | 35 |

SPECIFICATION

PROCESS