Categories

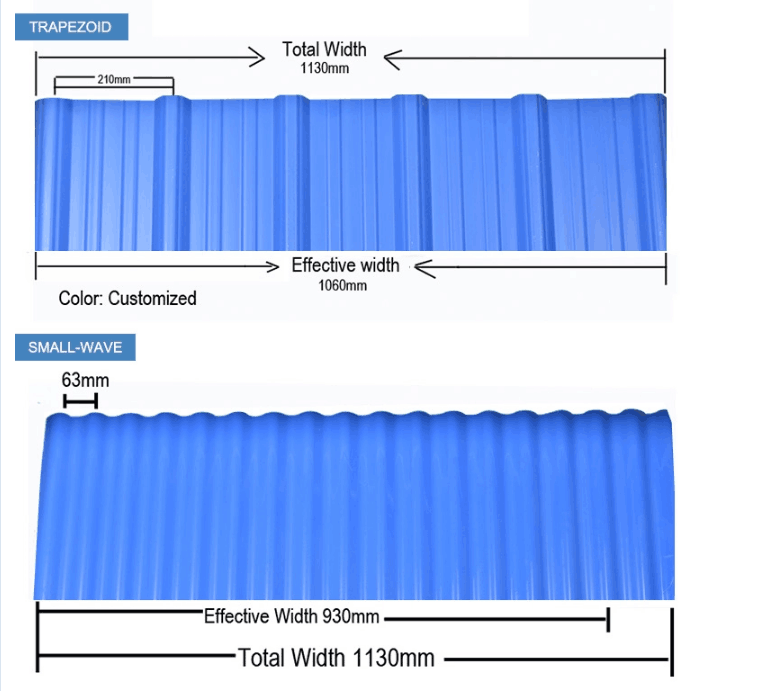

UPVC corrugated plastic roofing panels

UPVC corrugated plastic roofing panels

Business type: Manufacturer

Brand: YUEHAO

Origin: Foshan, GD, China

Target market: South America, Mid-East, Africa, Asia

Grade: A,B,C,D

MOQ: 200 SQM

Supply ability: 10000SQM/DAY

Delivery time: 3 to 15 days

Certificate: ISO, SGS ,FQM,MA,AL

Loading port: Sanshui/ Shenzhen/Guangzhou Guangdong, China

Payment terms: T/T, L/C,

Packing: Nude Packing or pallet packing, customized.

Business type: Manufacturer

Brand: YUEHAO

Origin: Foshan, GD, China

Target market: South America, Mid-East, Africa, Asia

Grade: A,B,C,D

MOQ: 200 SQM

Supply ability: 10000SQM/DAY

Delivery time: 3 to 15 days

Certificate: ISO, SGS ,FQM,MA,AL

Loading port: Sanshui/ Shenzhen/Guangzhou Guangdong, China

Payment terms: T/T, L/C,

Packing: Nude Packing or pallet packing, customized.

UPVC corrugated plastic roofing panels

The advantage of the PVC roofing sheet is the translucency of the panels.They allow daylight to enter through them. If cost is a factor, PVC roof sheet is a cheaper alternative to sheet metal. PVC panel will block out the heat from the sun much more effectively than sheet metal, which will act like a radiator.

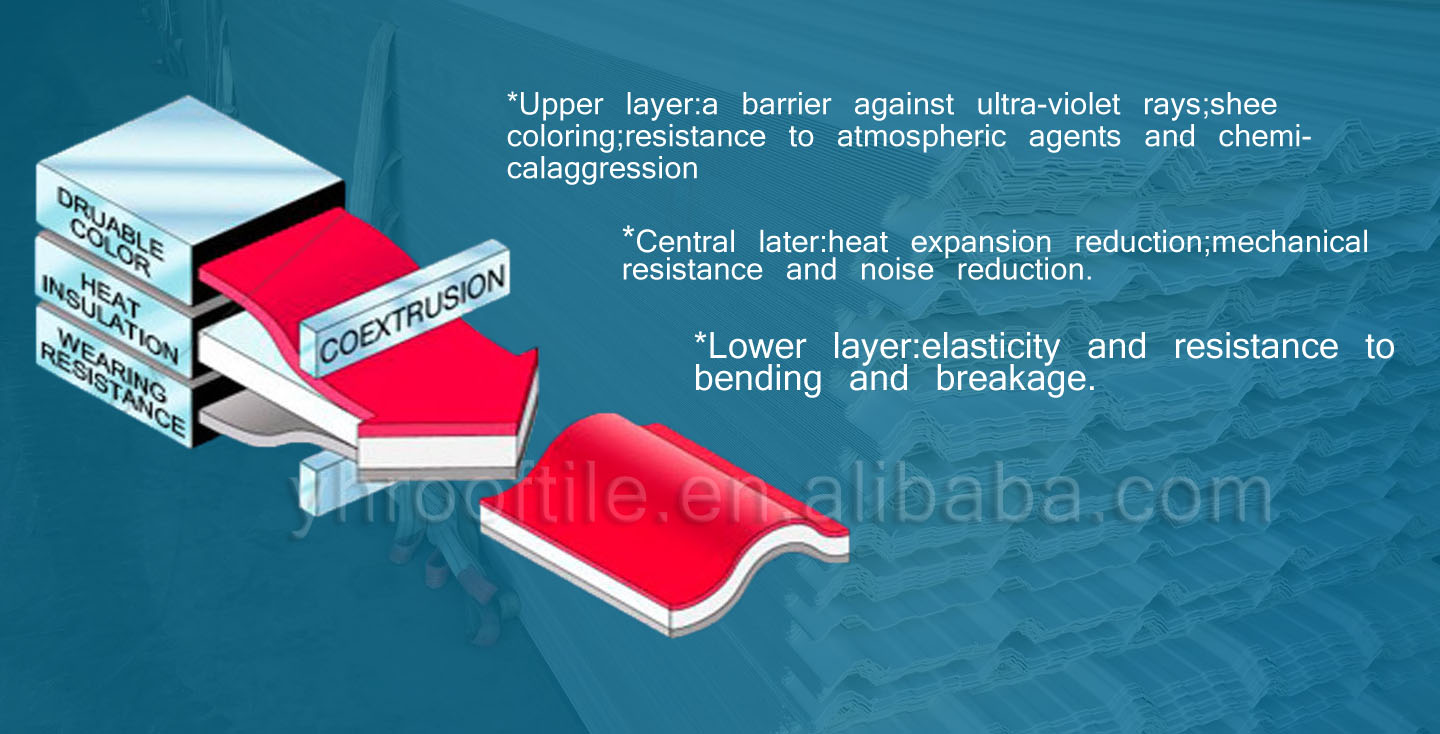

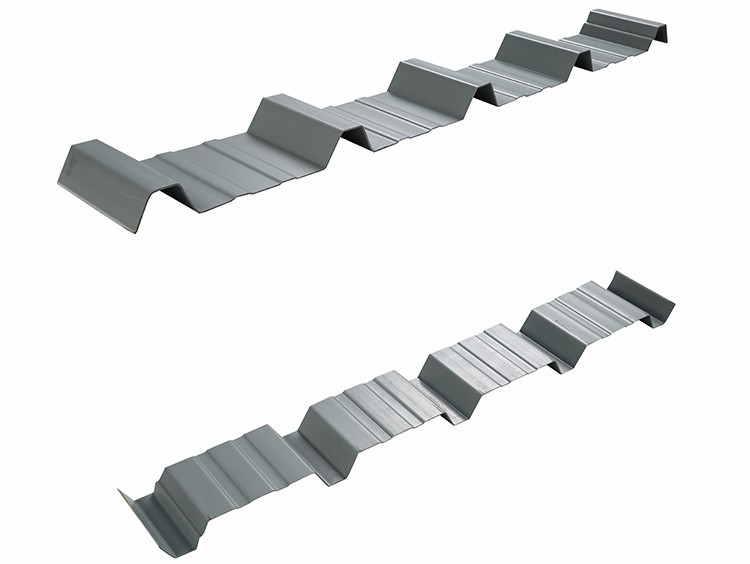

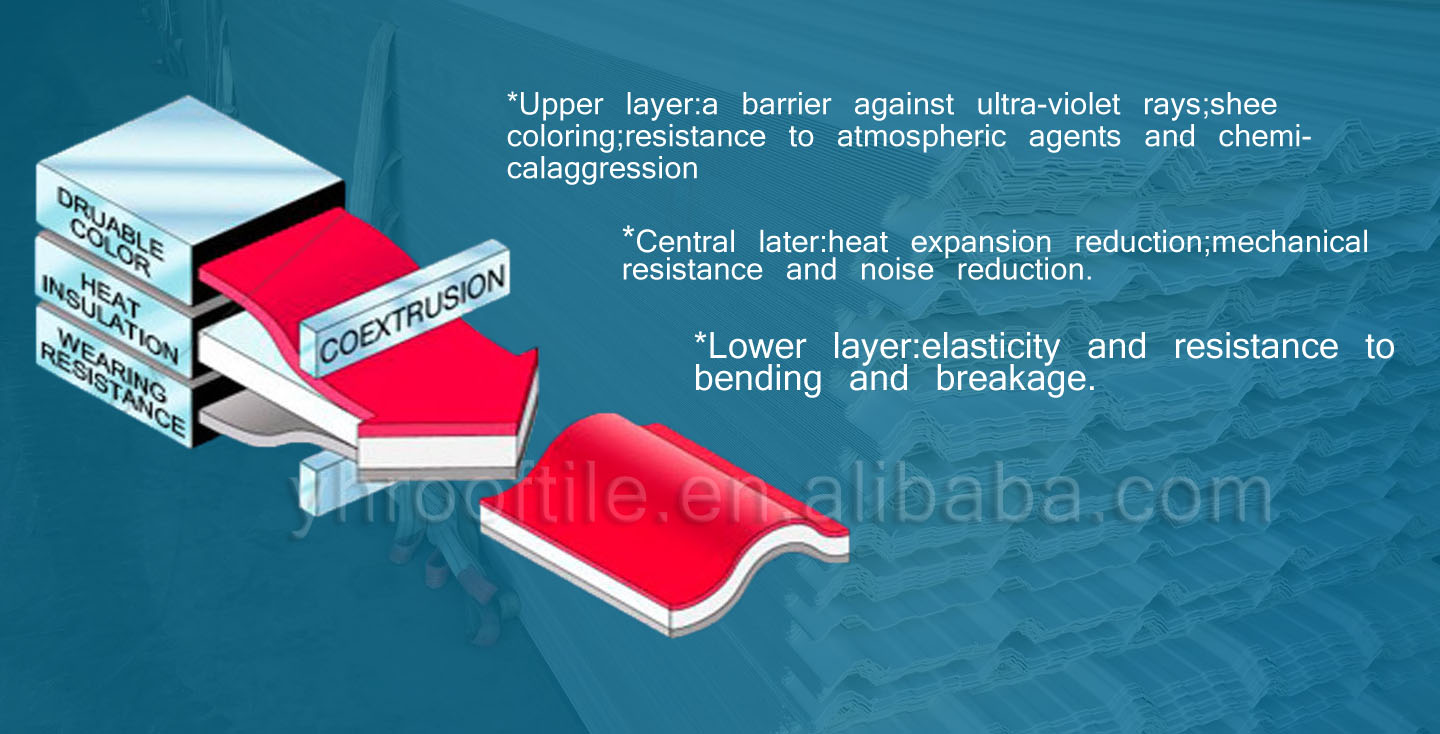

3 layer Heat Insulated UPVC Roof Sheet is manufactured based on 3 layer co-extrusion technology by one-time processing. It is an ideal building material for construction projects with heat insulation requirement. The following is a list of the distinct features of each layer material.

First layer: weather resistant resin is selected as the top layer material to block the solar ultraviolet radiation and reduce the coefficient of heat conductivity. It provides our UPVC roofing material with great durability and chemical corrosion resistance;

Second layer: the middle layer is a special foam structure with heat and sound insulation performances.

Third layer: the bottom layer of our heat insulated UPVC roof sheet adopts modified PVC material to offer optimum strength and rigidity.

3 layer PVC roof sheet is made by the production processing technology called co-extrusion. Due to this processing, the roof sheet can offer multiple functions, with each layer has its special feature.

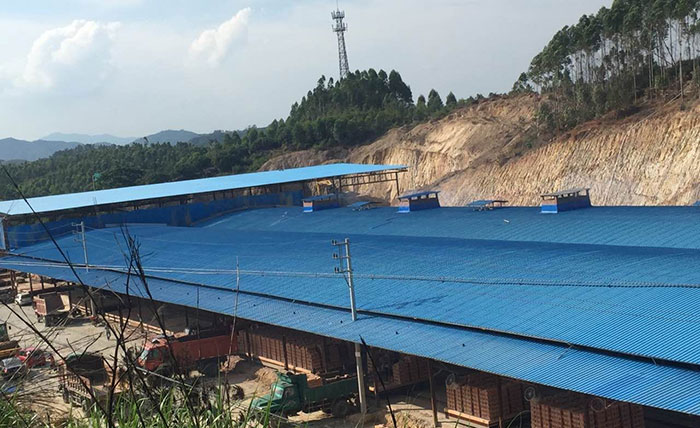

PVC roof sheet is the most popular among customers because of its good features and competitive price. They are widely used in carport, depot, gazebo, warehouse, wall cladding, farm land, airport, station...

-Roofs aren't for standing on. There's a good chance you'll damage a corrugated roof by standing on it. Therefore, when installing PVC roof sheet, we’d better step on the position where supported by purlins or trusses.

-On a corrugated roof, always fix at the top of the ridge to minimize the run -in of moisture.

-Do not drill holes for the screws in the valley of the ridges to prevent leaks.

-Next, pre-drill holes on the end and side ridges of the panels, spacing the holes 6 to 8 inches apart.

-Beginning at the outside edge of your roof, place each panel directly onto the purlins that are attached to the roof trusses.

-Screw down the panels using the pre-drilled holes, then continue across the roof until it is completely covered!

Nude packing for FCL loading

PE bag packing for bulk loading

Prodyct description

3 layer Heat Insulated UPVC Roof Sheet, manufactured based on 3 layer co-extrusion technology by one-off processing, is an ideal building material for construction projects with heat insulation requirement.

Advantages of pvc roof sheet

The advantage of the PVC roofing sheet is the translucency of the panels.They allow daylight to enter through them. If cost is a factor, PVC roof sheet is a cheaper alternative to sheet metal. PVC panel will block out the heat from the sun much more effectively than sheet metal, which will act like a radiator.

3 layer Heat Insulated UPVC Roof Sheet is manufactured based on 3 layer co-extrusion technology by one-time processing. It is an ideal building material for construction projects with heat insulation requirement. The following is a list of the distinct features of each layer material.

First layer: weather resistant resin is selected as the top layer material to block the solar ultraviolet radiation and reduce the coefficient of heat conductivity. It provides our UPVC roofing material with great durability and chemical corrosion resistance;

Second layer: the middle layer is a special foam structure with heat and sound insulation performances.

Third layer: the bottom layer of our heat insulated UPVC roof sheet adopts modified PVC material to offer optimum strength and rigidity.

Materials

3 layer PVC roof sheet is made by the production processing technology called co-extrusion. Due to this processing, the roof sheet can offer multiple functions, with each layer has its special feature.

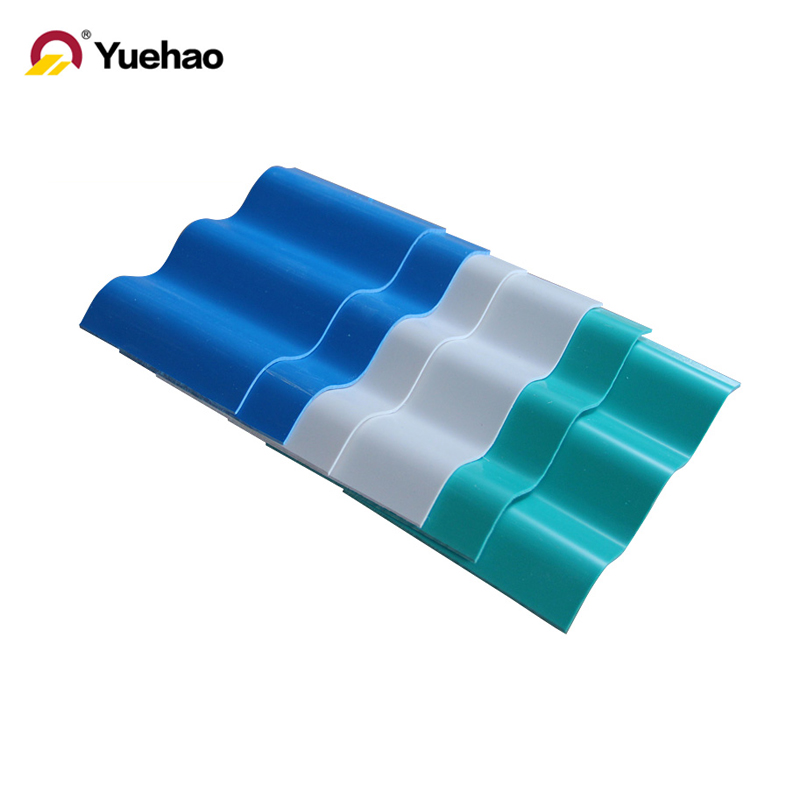

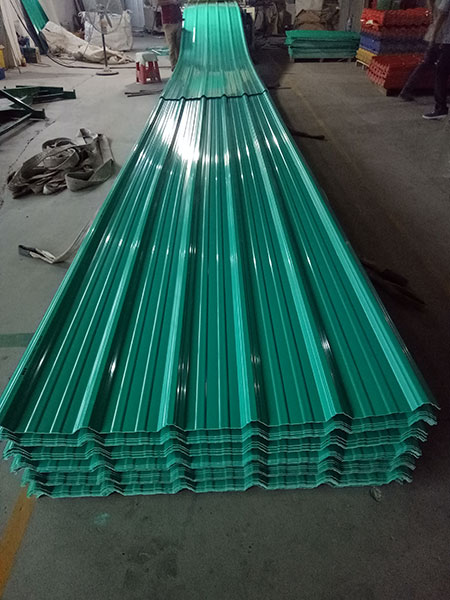

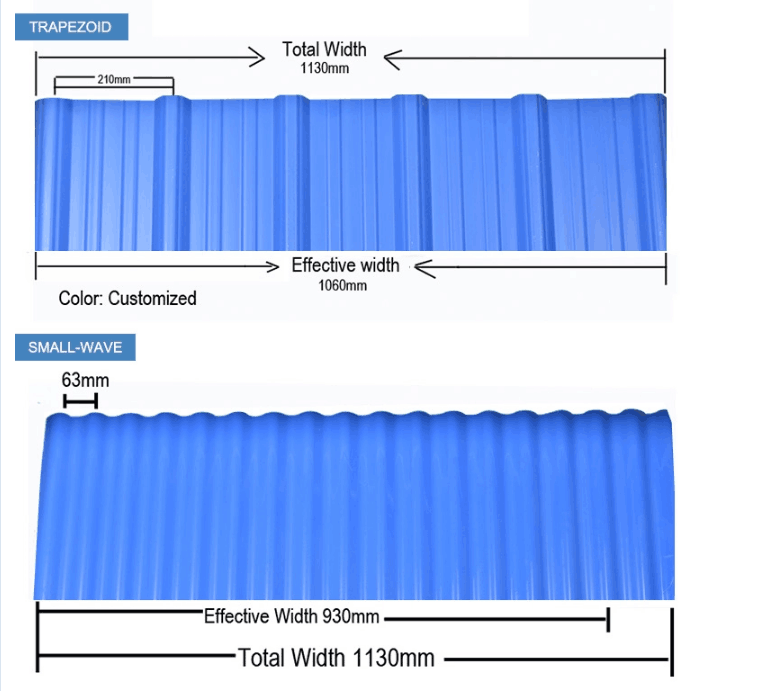

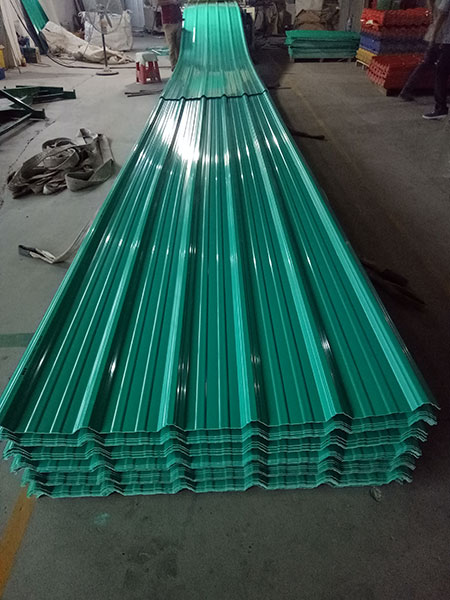

Color options

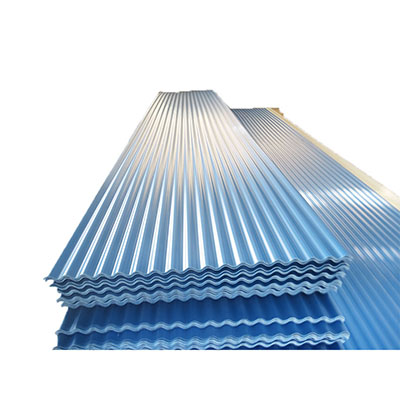

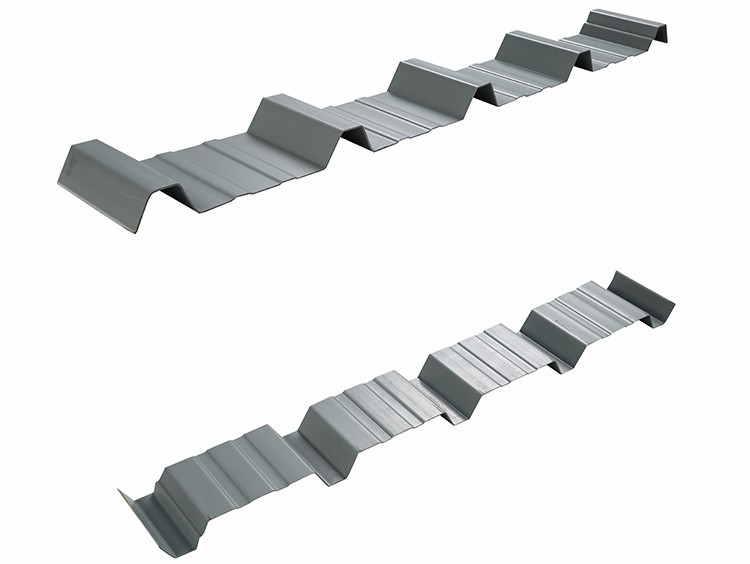

Picture display

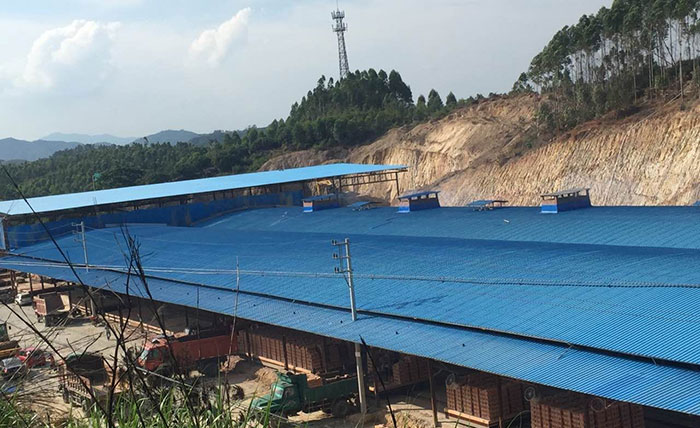

Cases/application

PVC roof sheet is the most popular among customers because of its good features and competitive price. They are widely used in carport, depot, gazebo, warehouse, wall cladding, farm land, airport, station...

Tips of install

-The purlins support the panels. If you are placing PVC sheets over an existing roof, you still use purlins. The purlins not only give you something other than the existing roof to accept the roof sheet fasteners, they also create an airspace between the roof sheets and the existing roof. Without the purlins, the roof sheets would sit directly on the existing roof, you would get moisture building up under the roof sheets.-Roofs aren't for standing on. There's a good chance you'll damage a corrugated roof by standing on it. Therefore, when installing PVC roof sheet, we’d better step on the position where supported by purlins or trusses.

-On a corrugated roof, always fix at the top of the ridge to minimize the run -in of moisture.

-Do not drill holes for the screws in the valley of the ridges to prevent leaks.

Summery

-To install corrugated roofing, start by cutting your panels to length with an angle grinder.-Next, pre-drill holes on the end and side ridges of the panels, spacing the holes 6 to 8 inches apart.

-Beginning at the outside edge of your roof, place each panel directly onto the purlins that are attached to the roof trusses.

-Screw down the panels using the pre-drilled holes, then continue across the roof until it is completely covered!

Shipping & loading

| Thickness | 2.4mm | 2.8mm | 3.0mm | 3.5mm |

| 20 container | 5400sqm | 4700sqm | 4300sqm | 3700sqm |

| 40 container | 5700sqm | 4900sqm | 4600sqm | 3900sqm |

Nude packing for FCL loading

PE bag packing for bulk loading

Certificate